The old saying “Kick the tires” has more meaning than you’d guess. Commercial and general aviation pilots do this on a routine basis. But why? Just ask Forrest Gump: “It happens.” Stuff does happen as we RVers chalk up the miles on our asphalt journeys.

For many years in our business, our mode of transportation was our plane we extensively used visiting customers and vendors. One day we gave up three wheels and high speed for six wheels at moderate speed. And as full-timers, we’ve learned a lot. Neither of us shy, so as we meet others, there’s usually an interesting topic-the reason that brought us together in the first place.

During our first two years of RVing, we averaged 20,000 miles annually exploring diverse climates, topography and culture. In 2019, we raced south just hours ahead of the winter storm that blanketed Yaak Valley, Montana with a few feet of snow. Notwithstanding, traveling that many miles doesn’t go without dedicated routine maintenance and minor repair issues here and there as the rubber meets the road.

Sooner or later saga

Subjects that are not vehicle specific, such as wheels and tires, oil and filter changes, generators and chassis maintenance, we gleaned relevant insight from Freightliner, long-haul truckers and fleet facilities as well as our motorhome’s cottage industry facilities as several of these topics cross-pollinate to motorhomes. As the full-timer’s saying goes… sooner or later you’ll experience your share of operational problems. It’s inevitable. Try putting your house on wheels and traverse the country for thousands of miles without a hiccup or a rattle. Potholes and railroad crossings are inevitable. They’ll make your rig shake, rattle and roll, especially the ones you can’t see until it’s too late.

Keeping your engine healthy

When traveling with a diesel pusher the very first thing my hubby checks each morning while the engine is cool is its oil level. We always carry extra quarts of oil and add a little if needed. He’s a stickler when it comes to routinely changing the oil (and filter), usually in advance of its future service mileage change. We also carry an extra oil filter, even if we service our rig at a facility. Depending upon where you are geographically, your specific make of oil filter may not always be readily available. That holds true for older coaches. So, we carry extra parts for this specific purpose, and you can save the mark-up on the facility’s invoice for providing your own oil filter.

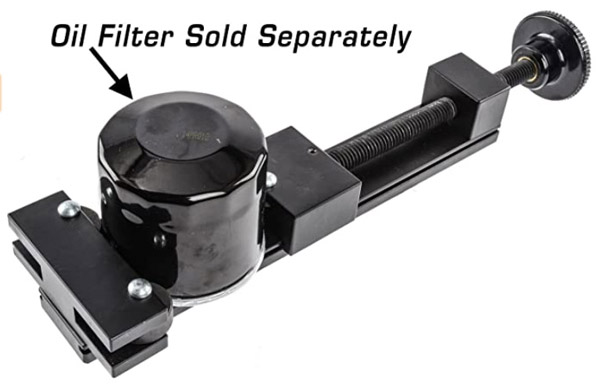

When changing the oil filter, my hubby cuts through the used oil filter with a special JEGS tool and runs the residual oil between his fingers to feel for grit or minute metal shavings. You can read more on this subject in the article titled “Is your engine in good shape? You can pay now or pay later” from this site: endlessvoyages.com in the category maintenance/repair. It focuses on folks who know engines giving you, the consumer, tips to keep your engine running smooth.

You can go one step farther and run a rare earth magnet over the filter. It will grab any metal shavings that may be present. Rare earth magnets are available in most hardware stores. Should there be any residual in the oil, it would be wise to take the filter to an auto parts store or send it out and have it analyzed which may foretell if your engine’s cam shaft, crankshaft, pistons or connecting rods may be developing a problem.

Where the rubber meets the road

According to the FMCSA (federal motor carrier safety administration) the rules that apply to commercial vehicle inspection makes total sense. It is a requirement for all CDL drivers to inspect their vehicle and sign off that it is in good working order before taking off. Most will double-check the lug nuts on any transport before driving. It’s simple, grab each and see if they are loose. If you find a loose one on your rig, call for the mobile tire truck to re-torque each lug nut on all tires! It’s doubtful any of us carries the proper torque wrench needed to deliver specified rotational force (or torque).

Check the rims

While you’re doing that, check the rims for cracks. Check the inside rim for brake fluid leakage. There is no diagram or arrow to point where to check. It will be obvious. The fluid will run to the ground. How do we know this? We had a brake fluid seal wear out and leak in our left front steer tire. The break cylinder rubber seal wore out. Brake fluid is quite caustic and over time this rubber seal gives with the action of the plunger pushing fluid through the cylinder. Once again, the roadside assistant came to the park we were staying and replaced the brake cylinder seal.

Replacing a tire

When replacing a tire on your motorhome, whether by roadside service or in a facility, the technician uses a heavy-duty torque wrench to properly tighten the lug nuts. At some point, you’ve may have watched a NASCAR pit crew change a tire in seconds with that familiar whining sound right before the race car squeals away reentering the race. So, it’s likely that most of us RVers don’t readily carry the torque wrench to deliver the proper rotating force (torque) required for 22.5-inch tires, either eight or ten stud. We have a freightliner chassis, and they suggest the wheel nuts to be ‘torqued’ between 280- and 310-foot pounds (380 to 420N∙m). Check with the facility or your chassis’ tire specifications if you decide to do this yourself. I’d bet most of us won’t try to wield these heavy tires without proper tools.

When damage occurs

Visually inspect the tread and sidewalls for scrapes, cuts and punctures by nails, screws or other debris that may have been on the ground, especially prevalent in construction areas. Last summer we were pulling into a campground in Utah. After we had parked and began hooking up for the night, I had just opened the electric bay to grab our cord and noticed a “V-shaped” gouge in the back load tire on the driver’s side. That tire had only about 2700 miles on it. We didn’t transverse any road construction or visibly see any debris on the highway that we noticed. Origin unknown. It could’ve happened while pulling off the highway or into the RV park. Either way, our roadside assistance service changed the tire expeditiously, albeit we had to buy a brand new $900 tire as the one we discarded measured at 28/32 tread and the tech classified it as new on the tire report. I would rather have earmarked the $900 for something else. Remember “It happens.”

Tire pressure gauges

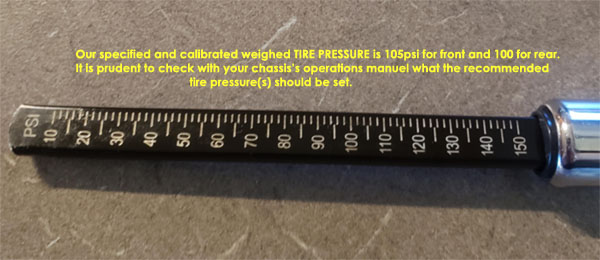

When it comes to tire pressure, there are a variety of gauges to choose from. The round tire gauge is only good for automobiles etc., as it only reaches a maximum of 60psi. Not suitable for motorhomes riding on 22.5-inch tires that are typically inflated at 100psi and higher. We have a compressor built in our motorcoach, so inflating them is not a problem. But it’s gaining a better understanding of proper pressure for climate and temperature changes. The gauge that we’ve witnessed long-haulers use is this one or a similar gauge. It costs more, but it is far more accurate than the pocket gauge.

Tire pressure

Tire pressure is another item we all take for granted. When following or passing another RV or trailer, we’ve witnessed tires that are running with noticeably low pressure. Perhaps they have a sharp object imbedded causing leakage. But, by the time we’ve passed the RV, it is difficult to hail them down or tell them one of their tires is low. So, it’s a learned trait. You can’t check your tires enough.

Should we use a Bluetooth pressure monitor

The first year, we purchased a tire pressure monitor only to find its readings were less than optimum as it sent out false numbers and intermittently skipped certain wheels, not displaying their numbers. Before we purchased the monitor kit, we double checked that this Bluetooth monitor would send signals the entire length of our coach, including our tow vehicle as advertised. The Bluetooth sensors are located inside the valve stem caps and we affixed the display monitor next to our GPS on the console. It started working but as the miles piled on during the day, it would skip a wheel reading five of the six, and sometimes miss one of the four tow vehicle wheels. It always seemed to skip one of our rear inside tires. It wasn’t picky. It would alternate when it felt like it.

In the beginning, we would pull into a roadside rest area and check the tire, valve stem cap etc. And, of course, we didn’t lose the tire. So, after talking to their techs, who mentioned our coach was too long and the sensor should be toward the back of the vehicle, we said, “How can you monitor the tires if the digital gauge is not within eyesight? What good is a gauge that is in the bedroom, not on the driver’s console?” So, hubby placed the monitors back in its box. Oh well!… Back to basics. Old-fashioned check and recheck.

On a CDL vehicle or airplane, drivers routinely check tire pressure before every outing. Yes, we’ve blown a tire on landing, so what good was the gauge? Gauges are only as good as monitoring weak and stress points like tread wear, accidental overinflation or hitting something. The gauge can only alert us to a problem, but it can’t fix it. Blowouts happen spontaneously, very seldom there is a warning. My hubby checks the tire pressure every morning when we are traveling. And at every interim stop, he does another “kick the tires” walk-around visually looking for serious wear and tear or damage.

Tread wear

Tread wear requires a visual inspection. You hope that your tires are wearing evenly and that correlates to your rig’s wheels proper alignment. What you don’t want to have happen is blow a tire or cause a flat on one of your load tires and replace that tire with a tire whose aspect ratio is different in size than the other tire (inside or outside). This will quickly cause uneven wear in the opposing tire, putting the new tire or its mate in danger of a blowout. How do we know about aspect ratios? When we had our tire changed in Utah, the roadside assistance folks at the call center ordered a steering tire with a different aspect ratio. In other words, the steering tire’s overall dimensions were larger in diameter than the load tire. When the technician brought the first tire, my hubby immediately said, “This is a steering tire, not a load tire. I ordered a load tire.” The technician stated, “We’re required by the roadside folks to only install steering tires.” That’s fine if you have the same tire all the way around, but when you don’t it’s a disaster waiting to happen.

My hubby told the tech to take that tire back and replace it with the proper aspect ratio load-bearing tire, preferably the same brand. The tech agreed, stating to us that not many folks would even challenge this issue. But it was obvious when comparing the tires that the tread pattern was vastly different for obvious reasons. So, when the tech returned with the proper tire, it was reaffirmed to be the right tire.

Use your senses: (look, listen, smell, feel).

- Check critical items when you stop:

- Tires, wheels and rims

- Brakes

- Brake lights, turn signals and reflectors

- Brake and electrical connections to trailer

- Trailer coupling devices (tow bars, safety cables, bracket and clevis pins)

- Cargo securement device

Before driving, check for brakes, signal lights and that your tow vehicle is rolling freely forward. In an article I recently read for RVing, a RVer was towing a new jeep. The tow vehicle’s brake hadn’t released resulting in locked tires catching fire.

You may click here to purchase the identical heavy-duty tire pressure gauge:

BIO: Greetings from members F499712. My engineering spouse Brian and I are full-timers that haven’t quite “retired” yet…we like working, traveling and helping others. Whether its consulting for a start-up or helping streamline manufacturing, that’s us. I’ve been writing for over 30 years running the gambit from industrial, public service and general interest to corporate relations and FDA specifications. My spouse consults on engineering and manufacturing projects while we travel the US. You can read more than fifty published RVing articles on a variety of subjects in our BLOG endlessvoyages.com.

Where were you on 9/11? One of our previous businesses was working in and with the military/government on special operations projects. You’ll soon realize that if you read the author bio in this recently published work of fiction titled Masquerade: A Logan Scott Novel under the pen name “Bryan Alexander” available on Amazon.com: Masquerade in paperback or Kindle, Barnes & Noble and iBooks. It’s a page turner!